When it comes to the world of print media, presentation is just as crucial as the content it carries. As an author, business, or creative, understanding the various binding methods available can be the difference between a book that feels professional and one that lacks sophistication. One popular method that has found favor across a multitude of print applications is perfect binding. In this deep dive, we'll explore the ins and outs of perfect binding and why it might be the ideal choice for your next printing project.

What’s Perfect Binding

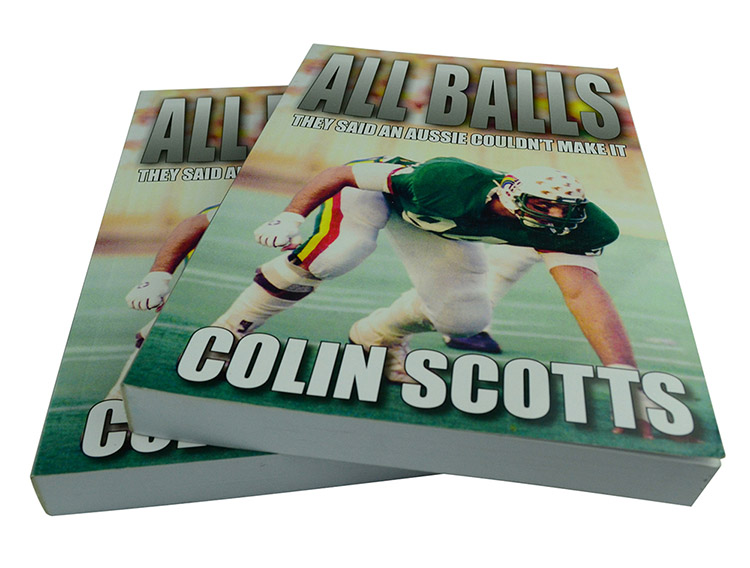

Perfect binding is a widely used bookbinding method where a flexible adhesive attaches a paper cover to the spine of the assembled signatures, which are the groups of pages that make up the content of the book. Think about the paperbacks on your bookshelf; that's perfect binding in action. It creates a sleek and sturdy finish that's not only attractive but also cost-effective.

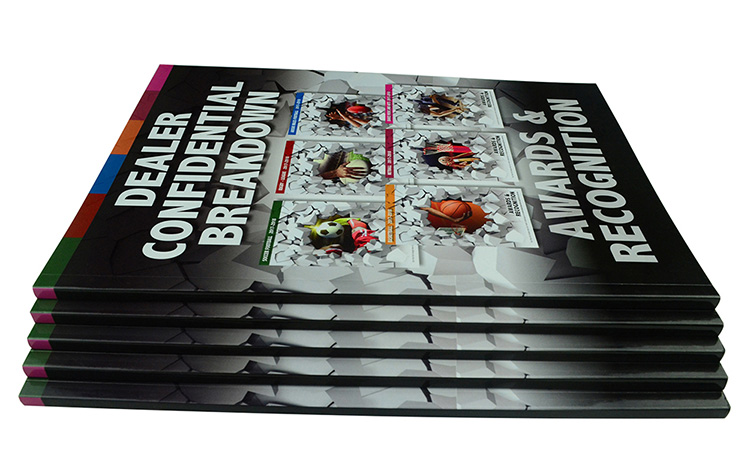

One of the hallmarks of perfect bound book printing is its flat spine. Unlike other binding methods that may expose the stitching or gluing, perfect binding encases all the workings within the spine. This gives it a seamless look and allows for spine artwork, which is essential for book identification when displayed on shelves.

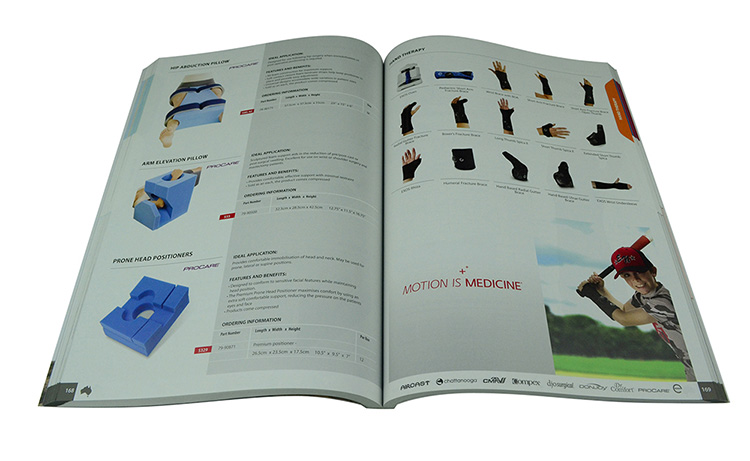

Perfect binding is not just about aesthetics; it’s about practicality, too. The adhesive used is strong enough to hold the pages together even with frequent use. It's a go-to choice for novels, catalogs, manuals, and magazines.

The Advantage of Perfect Binding

When considering perfect bound book printing, there are several advantages that make it an attractive option for publishers and authors alike.

First, perfect binding gives a professional appearance. The clean lines and flat spine convey a high level of craftsmanship and quality. It's an aesthetic that resonates with readers and speaks to the care put into the publication.

Another significant benefit is the cost-effectiveness of perfect binding. When compared to other binding techniques, such as hardcover or spiral binding, perfect binding often comes out as the more economical choice, especially when considering wholesale book printing. This makes it an accessible option for print runs of all sizes, from small batches to mass distribution.

Moreover, perfect binding allows for versatility in design. The spine can accommodate text and graphics, enabling full use of the cover for branding and titling. This is particularly useful for books that will be displayed on shelves. Because the spine is what's typically visible to potential readers first.

The Limits of Perfect Binding

While perfect binding offers many benefits, it's important to recognize that it isn't without its limitations.

One of the primary constraints is the durability when compared to other binding methods like case binding, which is typically used for hardcover books. Perfect bound books are more susceptible to pages becoming loose or the spine cracking if the book is opened too wide or handled roughly.

Another limitation is the thickness requirement for the spine. There needs to be enough pages to ensure that the spine is thick enough to hold the glue and keep the cover in place. This means that very thin publications might not be suitable for perfect binding.

Lastly, the flat spine of perfect bound books can be a double-edged sword. While it allows for spine printing, it doesn't lay flat when open. It can be a drawback for certain types of publications, such as cookbooks or instructional manuals, where hands-free reading is preferable.

How Many Pages Are Needed for Perfect Binding

The question of how many pages are needed for perfect binding is a common one. Generally, the minimum number of pages for perfect binding to be effective and practical is 24 pages. This ensures that there is enough spine width to properly adhere the cover and secure the pages. On the other end of the spectrum, perfect binding can accommodate books with several hundred pages, making it a versatile choice for a variety of projects.

For those considering square perfect bound book printing, the page count can also influence the final look. Square-bound books have a distinctive appearance that can make your publication stand out. However, the same page count rules apply — there needs to be sufficient thickness to form a spine that can be glued effectively.

When determining the page count for your perfect bound book, it's also crucial to note that the pages need to be printed in multiples of four. This is because the sheets of paper are folded in half to form the signatures that make up the book. This requirement should be taken into account during the design phase to avoid any last-minute adjustments or blank pages.

The Process of Perfect Binding

The process of perfect binding is a multi-step endeavor that transforms loose printed sheets into a cohesive, polished book. Understanding the steps involved can help you appreciate the intricacies of this binding method. And then make informed decisions when working with perfect binding book printing suppliers.

The first step is the gathering and collation of the printed signatures. These are the groups of pages that have been printed and folded in preparation for binding. Each signature represents a section of the book, and when they are stacked together in the correct order, they form the complete text block.

Next, the spine edge of the text block is roughened or milled. This creates more surface area for the adhesive to bind to, which is crucial for the longevity of the book. The spine is then coated with a strong, flexible glue that is specially formulated for perfect binding.

After the glue is applied to the spine, the cover — which is usually a heavier paper stock and includes the front, back, and spine — is placed around the text block. The book is then clamped together until the glue dries. Once dry, the edges of the book are trimmed to give them clean, sharp lines, resulting in the final product.

When You Should Consider Perfect Binding

Perfect binding is an excellent option for a variety of printing projects, but there are certain scenarios where it truly shines.

If you're publishing a novel, a memoir, or any form of narrative literature, perfect binding adds to the reading experience by providing a sleek, bookshop-quality finish. It also lays a professional groundwork for self-published authors looking to make a strong impression in the market.

For businesses producing reports, catalogs, or company profiles, perfect binding presents the information in a format that is both easy to handle and aesthetically pleasing. It suggests a level of professionalism and permanence that can elevate the perceived quality of the company's offerings.

Educational materials, such as textbooks or supplementary workbooks, also benefit from perfect binding. The method allows for the production of volumes that are robust enough to withstand repeated use. While still being affordable enough for educational institutions to supply them to students.

When choosing perfect binding, it is important to consider factors such as the purpose of the book, the desired quantity, and your budget. If you are looking for a cost-effective solution for a large print run, perfect binding is a great choice. Additionally, if you want to showcase high-quality graphics or images on the cover, perfect binding allows for excellent customization options.

Difference Between Perfect Binding and Sewn Perfect Binding

While perfect binding typically refers to the adhesive method, there's a variant known as sewn perfect binding that you might encounter. The main difference lies in the additional step of sewing the signatures together before gluing them into the cover. Sewn perfect binding offers enhanced durability and allows books to lay flat when opened, which can be a significant advantage for certain types of publications.

However, this added sturdiness comes with increased production costs. Sewn perfect binding is more labor-intensive and requires additional materials, making it a more expensive option. It's worth considering for books that are intended to be kept and used for many years, such as art collections, commemorative editions, or high-use textbooks.

Design Tips for Perfect Binding Books

When designing a book for perfect binding, there are several considerations that can help ensure a successful final product.

First, you'll want to account for the creep, which is the slight shift of content towards the spine on each page as they stack up. This is particularly important for books with a high page count or thicker paper.

Additionally, when laying out your cover, remember to include the spine in your design and ensure that the text and graphics are centered to accommodate the fold. The cover will wrap around the spine, so providing a little extra material — known as the bleed — is necessary to ensure a clean finish after trimming.

Lastly, consider the paper type and weight for both the cover and interior pages. A heavier cover stock will give your book durability, while the interior paper should balance readability and thickness. A reputable perfect binding printing service can guide you in choosing the right materials for your project.

In conclusion, perfect binding is a versatile and professional choice for a wide range of printing needs. Whether you're an author looking to self-publish your novel, a business creating promotional materials, or an educator assembling resources, perfect binding offers a blend of aesthetic appeal, durability, and cost-effectiveness that is hard to beat. Keep these insights in mind as you embark on your next printing adventure, and you'll be well on your way to creating a perfect bound book that stands the test of time.

Chinaprinting4u has over 28 years of high quality book printing experience, whether you need to print a novel, a catalog or other projects, we can do it with our powerful offset printing technology. Talk to us today, let's help you save 30%-40% of printing budget.