|

|

-

-

- Help

-

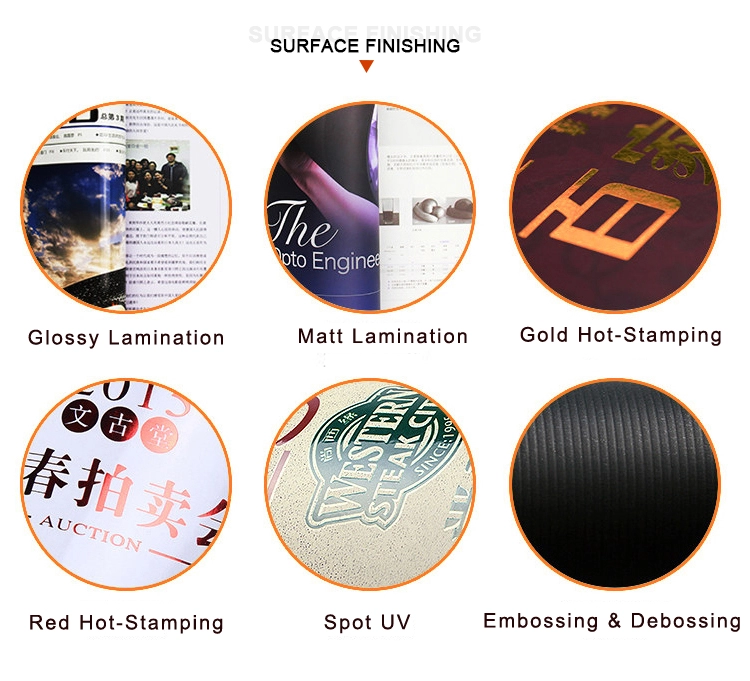

- Cover Surface Options

Help

Help- How to order

- FAQ

- Prepress Artwork

- Order procedures

- Shipping Methods

- Cover Surface Options

- Quality Class

- Payment Account

- Production Time

- Paper Options

- Binding Way

- Printing Size

Contact Us

Contact Us-

-

86-13580851182

-

Chinaprinting4u

-

www.chinaprinting4u.com

-

The No.601-605 First International E buidling Nancheng Dongguan Guangdong China

When it comes to printing, the cover of a document or publication is often the first thing that catches the eye. It serves as a visual representation of the content inside, making it crucial to choose the right finish for the cover. At Chinaprinting4u, we offer a wide range of cover options to enhance the appearance and durability of your printed materials.

Lamination

One of the most popular cover finishes is lamination. It involves applying a thin layer of plastic film to the surface of the cover, providing protection against moisture, tearing, and general wear and tear. Lamination also adds a glossy or matte finish, depending on your preference.

Glossy lamination: Glossy lamination gives the cover a shiny and reflective appearance. It enhances the colors and patterns on the cover, making them more vibrant and eye-catching. This finish is particularly suitable for designs with bright colors and high-resolution images. Additionally, glossy lamination adds a layer of protection, making the cover more resistant to scratches and fading.

Matte lamination: If you prefer a more subdued and elegant look, matte lamination is an excellent choice. It gives the cover a smooth and non-reflective finish, reducing glare and fingerprints. Matte lamination works well for designs with a minimalist aesthetic or for materials that require a more professional and sophisticated appearance. Like glossy lamination, it also provides durability and protection.

Foil stamping

For a touch of luxury and sophistication, foil stamping is a cover option that stands out. It involves applying a metallic or pigmented foil to the cover using heat and pressure. This process creates a shiny and eye-catching design or text on the cover, enhancing its visual appeal.

Foil stamping can be used to add text, logos, or decorative elements to the cover. It is commonly used for book covers, cards, invitations, and packaging. The metallic shine of foil stamping instantly grabs attention and adds a touch of elegance and prestige to your printed materials. Whether you want to create a bold and striking design or add subtle accents, foil stamping is an excellent choice for enhancing the visual appeal of your cover.

Spot UV

Spot UV is a technique that involves applying a glossy, clear coating to specific areas of the cover, creating a contrast with the rest of the surface. It adds depth and dimension to the design, making certain elements stand out. Chinaprinting4u offers precise and high-quality spot UV printing, allowing you to highlight logos, text, or images on your cover.

Spot UV is commonly used for business cards, book covers, and marketing materials. By applying spot UV to select areas, you can create a visually striking effect that captures attention and adds a touch of sophistication. Whether you want to make your logo pop or draw attention to important information, spot UV is a versatile option that can elevate the overall look of your cover.

Varnish

Varnish is a transparent coating that adds a subtle shine and protection to the cover. It is applied to the entire surface of the cover, enhancing the colors and making them more vibrant. Varnish also provides resistance against fingerprints, smudges, and minor scratches. This cover option is suitable for a wide range of printed materials, from brochures to catalogs, and adds a polished and professional look.

Whether you want a glossy or matte finish, varnish is an excellent choice for adding durability and enhancing the overall look of your cover.

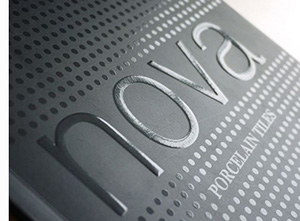

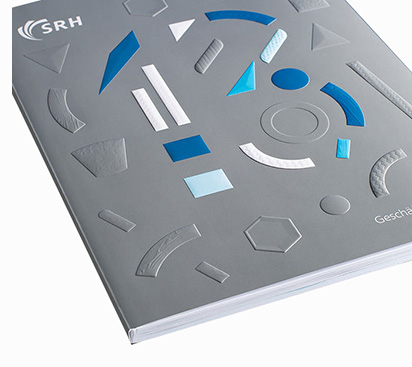

Emboss

Embossing is a cover option that creates a raised or three-dimensional effect on the surface. It involves pressing the cover against a metal die, which transfers the design onto the material. Embossing adds texture and depth to the cover, making it visually appealing and tactile. This technique is often used for logos, titles, or important elements that need to stand out.

Embossing is often used for book covers, business cards, journals, and invitations. It adds a sophisticated and luxurious touch to your printed materials, making them stand out from the competition. Whether you want to create an elegant logo or add intricate details to your design, embossing is a versatile option that can elevate the overall look and feel of your cover.

Deboss

Debossing is the opposite of embossing, as it creates a depressed or indented effect on the cover. It adds a subtle and sophisticated touch to the design, giving it a unique and tactile appearance. Debossing works well for minimalist and elegant designs, adding a sense of depth and luxury.

Debossing is often used for luxury packaging, business cards, and notebooks. It adds a subtle and sophisticated touch to your cover, making it visually appealing and memorable. Whether you want to create a minimalist logo or add texture to your design, debossing is a versatile option that can enhance the overall look and feel of your printed materials.

Die cut

Usually the die-cutting process is a technology that combines the die-cutting knife and the crimping knife in the same template to hollow out the shape of the material. Root die cutting allows various printed packaging to be presented in three-dimensional and curved shapes, and the various shapes and shapes created are more beautiful, refined and full of creativity. Die cutting is a cover option that involves cutting the cover into a specific shape or pattern. It allows for creative and unique designs, making your printed materials stand out from the crowd.

Die cutting is often used for business cards, invitations, pop-up books, and packaging to create memorable and visually appealing covers. Die cutting not only can used on the cover, also can apply on the interior pages, edges, etc.

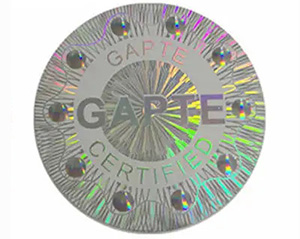

Laser foil stamping

Laser foil stamping is a printing technology that uses laser ink (with metallic optical color-changing anti-counterfeiting ink) and adopts advanced laser printing technology to screen-print or roll-print the laser ink on various flat and smooth materials. The printed matter can appear as the viewing angle changes. It produces different colors and has an obvious dynamic color changing effect. It can produce a rainbow ring effect under concentrated light, which can effectively improve the packaging quality. It creates precise and intricate patterns or text, giving the cover a high-end and artistic look. It can be used to create intricate designs or patterns on the cover, giving it a unique and modern look.

Laser stamping is commonly used for luxury brands, special editions, or products that require a personalized and exclusive touch.

Factors that affect deciding the cover options

When deciding which cover option is best for your project, several factors should be taken into consideration. These factors include the purpose of your printed materials, your target audience, your branding guidelines, and your budget.

1. Purpose of your printed materials

Are you creating a promotional brochure, a product catalog, or a corporate report? The purpose of your materials will influence the desired look and feel of the cover. For example, a glossy finish might be suitable for a vibrant and attention-grabbing brochure. While a matte finish might be more appropriate for a professional and sophisticated corporate report.

2. Think about your target audience

Who are you trying to reach with your printed materials? Understanding your audience's preferences and expectations can help you determine the most effective cover option. For instance, if your target audience consists of young and trendy individuals, a foil stamped cover might resonate with them. On the other hand, if your audience is more conservative and traditional, a varnish or embossing option might be more appealing.

3. Consider your branding guidelines

Your cover should align with your brand identity and convey the right message to your audience. If your brand is known for its sleek and modern aesthetic, a spot UV or debossing option might be a good fit. On the other hand, if your brand is all about luxury and elegance, a foil stamping or embossing option might be more suitable.

4. Consider your budget

Different cover options have different costs associated with them. While some options might be more affordable, others might require a larger investment. Consider your budget constraints and choose the cover option that provides the best value for your money..

The cover of your printed materials plays a crucial role in capturing the attention of your audience. At Chinaprinting4u, we offer a variety of cover options to enhance the appearance, durability, and overall quality of your printed materials. Contact us today to discuss your project and let us help you create stunning and professional printed materials that leave a lasting impression.

Tel/WhatsApp:

Tel/WhatsApp: