Book printing is a way to present one's own work, so book printing is particularly important. How are the various books we usually see printed? Let us to know more custom hardcover book printing processes.

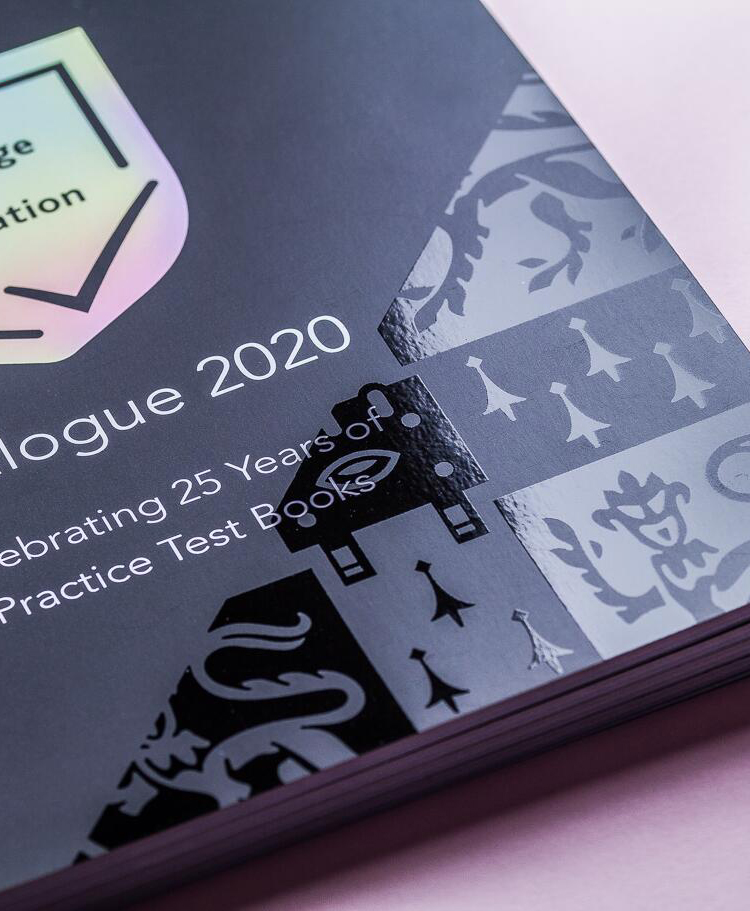

1. Bronzing process:

The bronzing process uses the principle of hot-pressing. To transfer the aluminum layer in the anodized aluminum to the surface of the substrate. To form a special metal effect. Because the main material of bronzing is anodized aluminum foil. Bronzing is also called anodized aluminum hot stamping.

The hot-stamped metallic luster has a strong decorative effect and strong visual impact.

2. Laser hot stamping:

It's transferring the laser pattern on the anodized aluminum to the substrate. By using the effect of temperature and pressure.

Its brush presents different colors with the change of the observation angle. Which has obvious dynamic color changing effect. And can produce a rainbow ring effect under the concentrated light.

3. Lamination process:

It also known lamination as over-glue. The lamination process has strong protection. Protects the printing color from scratches. And enhances the toughness of the printed product. The surface of the book cover after lamination is smooth and bright.

According to the different film materials. it classified as glossy film, matte film, pearlescent film and tactile film.

4. Die cutting process:

Usually the die-cutting process is a technology. Which combines the die-cutting knife and the crimping knife in the same template. To hollow out the shape of the material.

It's allows all kinds of printed packaging to present in three-dimensional and curved. Creating a variety of shapes and shapes. Are more beautiful, delicate and full of creativity.

5. UV:

It process is to cover the surface of the printed matter with UV ink to produce different bright effects. It is wide use in book design and production.

The UV process makes the printed matter show higher brightness. Transparency and wear resistance locally. The surface of the printed matter after partial UV treatment. Has a more textured and three-dimensional effect. Highlighting the visual effect of local light.

6. Embossing process:

The embossing process is to use negative (concave) and positive (convex) molds. To perform artistic processing on the surface of the printed matter.

Applying pressure from the front of the paper to indent the surface called a "dimple". Indentation is to use a single metal plate to press the graphic. Content of the thicker paper into it to form a unique concave feel.

7. Concave process:

The bumping process is one of the techniques in the post-printing process. The process of applying pressure from the back of the paper to make the surface swell called "bumping". The purpose of this process is to increase the layering of the structure.

The raised text on the cover in the picture uses the plain punching printing process. Which can present the raised figures or texts delicately, neatly and cleanly. Showing a unique punching process.

8. Brush edge process:

It is to use manual or digital technology to print different colors or graphics. On the edge of the book on the side of the paper.

The edging process includes: 1. Gold edging is hot stamping of various colors on the side; 2. Color spraying; 3. Silkscreen (screen printing colors on the side, including color patterns).

The edging process includes: 1. Gold edging is hot stamping of various colors on the side; 2. Color spraying; 3. Silk screen printing (color on the side, including color patterns).

The top of the book in the picture uses a silk-screen process, which can enhance the uniqueness of the book.

9. Laser hollowing process:

Its use the high energy density feature of the laser to irradiate the surface of the product. Cut the processed product through and produce a certain hollow pattern effect.

The circular or right-angle die-cutting processing of traditional post-press processing. Its limited processing accuracy. But the use of laser engraving can achieve many special graphics. And improve the accuracy of the product. Laser cutout makes prints, artistic.

Chinaprinting4u has more than 20 years of custom book printing experience. We provide the custom cookbook printing, children book printing,catalog printing, ect. No matter what kind of book you want to print, we can provide you with the best price and the highest quality.

Email:[email protected]

Email:[email protected] Tel/WhatsApp:+86 13580851182

Tel/WhatsApp:+86 13580851182