In the book printing field, we often with some Processes on the book to make it special or with some functions. Today I sort out 9 common book printing processes you need to know when custom your book printing.

With the development of digital technology, the emergence of online publishing and e-books. Some people's reading habits have changed. But many people still keep the reading habits from paper books. Paper books are physical objects, and those who can see and touch the unique book printing process. Which gives everyone an actual touch and is the charm of paper books.

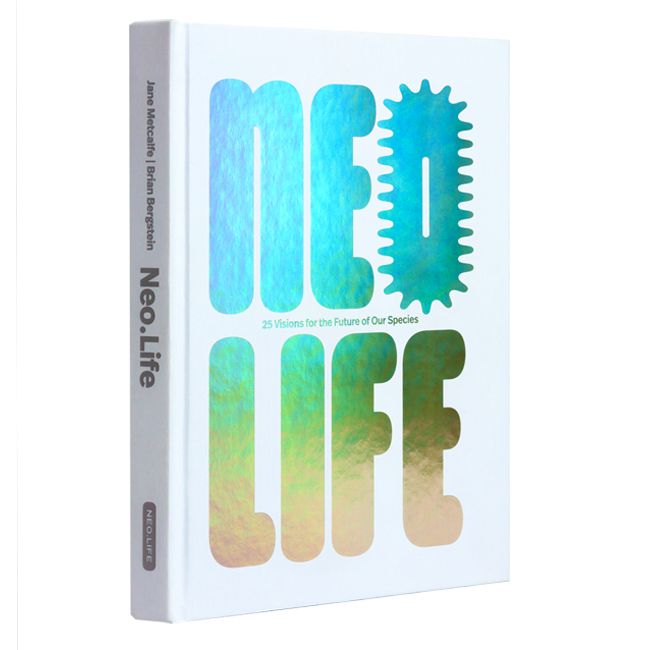

1. Hot stamping process

The hot stamping process uses the principle of heat transfer. To transfer the aluminum layer in the anodized aluminum to the surface of the printed matter to form a special metal effect. Because we anodize the major material used for hot stamping aluminum foil. Hot stamping, also known as anodized aluminum hot stamping.

Hot stamping makes the book with a special metal effect and strong visual impact. We usually used hot stamping in various of hardcover book printing.

2. Laser hot stamping process

Laser hot stamping process is using the effect of temperature and pressure. Transferring the laser pattern on the anodized aluminum to the printed matter.

With laser hot stamping process on the book surface. The book surface can show different colors with the change of the viewing angle. With obvious dynamic color changing effect. And can produce a rainbow ring effect under the spotlight.

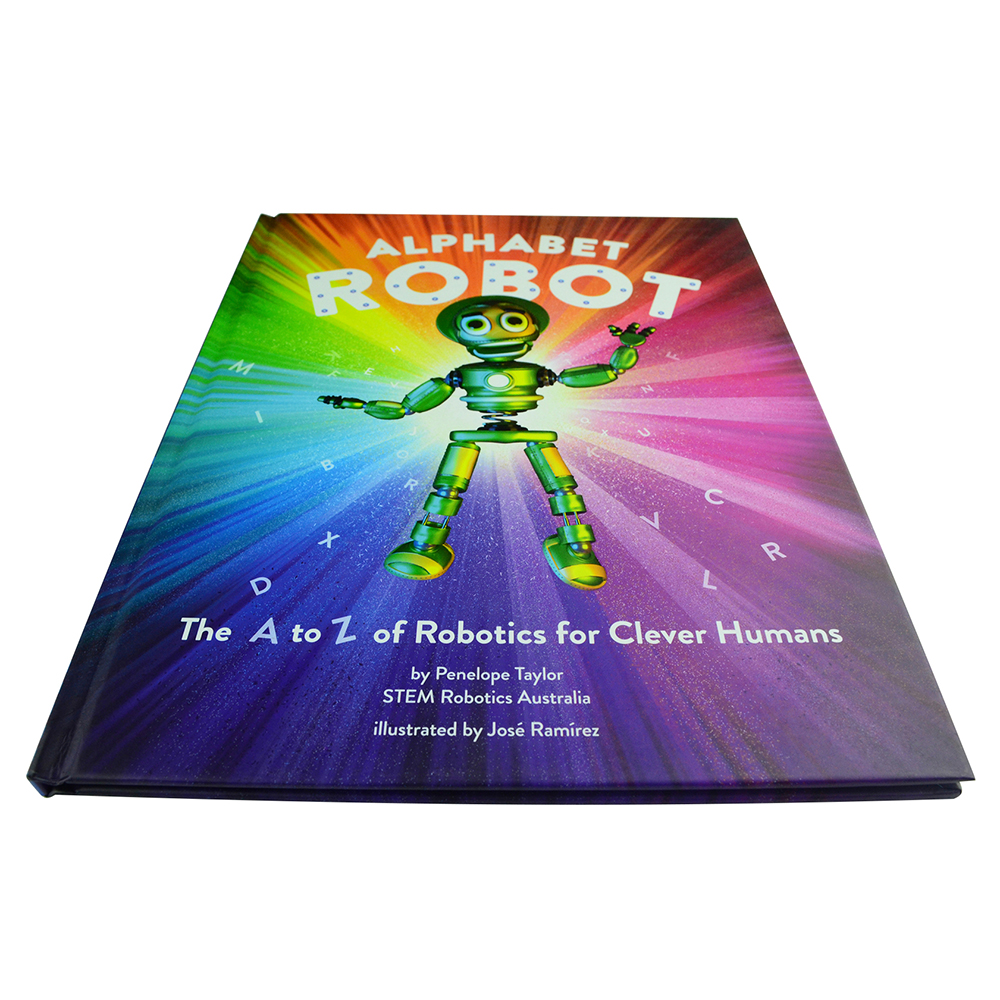

3. Laminating process

Lamination, also known as laminating. The lamination craft has powerful protection. Which can protect the printed color from printed books. And enhance the toughness of the printed books. The surface of the book cover after lamination is smooth, bright and waterproof.

According to different material. We often divide lamination into matte lamination, glossy lamination, touching lamination and pearlescent film. Among them, we often use glossy lamination in children’s book printing. To make the book surface more bright and attractive.

4. Die cutting process

Usually, the die-cutting craft is a technology. Which combines the die-cutting knife and the crimping knife in the same template to hollow out the shape of the material.

After die cutting, various of printed books look more stereoscopic, beautiful and with creative.

5. Spot UV process

Spot UV is use UV ink print on the printed book surface, to produce different glossy effect. We often use Spot UV in various of book printing. To achieve partial highlighting and brightening effects.

Spot UV makes the printed books with high brightness, transparency and wear resistance. After spot UV, the book surfaces with the visual effect of 3D and local high brightness.

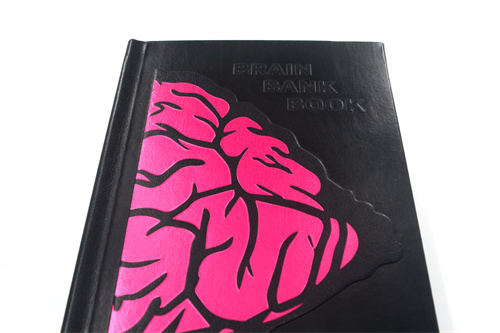

6. Emboss process

Emboss is using emboss mold to emboss the picture or logo on the printed book surface. To produce a special concave feel.

7. Deboss process

Deboss is also very common in the book printing field. Deboss is using the deboss mold to deboss the picture or logo on the book surface. To make the book surface with layer.

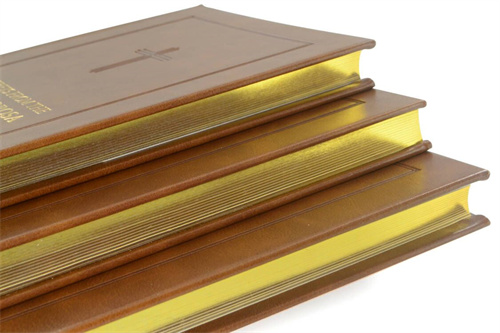

8. Brush edge process

The edge brushing process often uses manual or digital technology. At the side of paper, with different colors or pictures to print on the edge of the book.

Brush edge process includes glitter edge (hot stamping various of color on the edge); Spray color and silk screen (silk screen color or picture on the edge).The book with the brush edge process makes it more special.

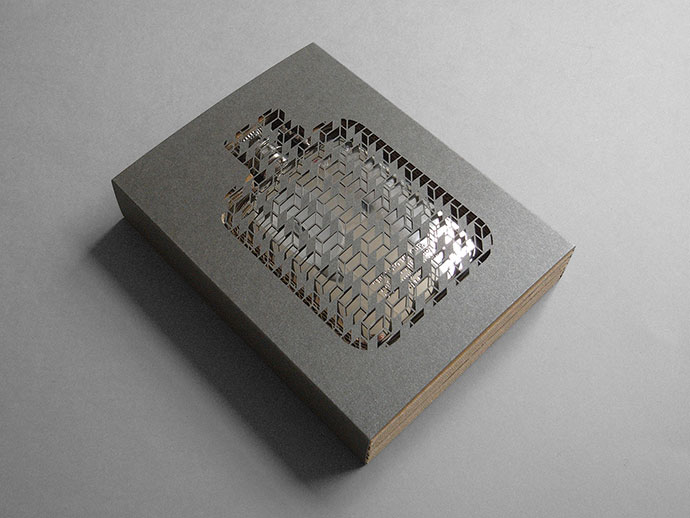

9. Laser hollowing process

Laser hollowing is to use the high energy density of the laser to irradiate the surface of the product. Cutting through the printed book and produce a certain hollow pattern effect.

The precision of round or right-angle die-cutting in traditional post-press processing is limited. But laser engraving can realize many special graphics and greatly improve the precision of products. Laser hollowing makes the printed book full of artistic sense.

Email:[email protected]

Email:[email protected] Tel/WhatsApp:+86 13580851182

Tel/WhatsApp:+86 13580851182