How

to reduce the cost of books is the concern of each of our publishing workers.

As Chinese printers,

should be proficient in plate making, printing technology, book printing cost standards,

understand paper specifications and performance and the production capacity of

relevant printing plants. In the printing work, according to the production

capacity of the printing plant, the plate making and printing process and the

selection of paper materials should be arranged reasonably to reduce the cost

of books.

Every

time a book is made, the overall design needs to be carried out by the

designer. The designer must design according to the content, nature, total

number of graphics and text, and readers. The cost of books is an important

factor in the competition in the book market. Now let’s talk about how to reduce

the cost of books from the perspective of pre-press printing.

1.

Paper opening

If

the format selection is unreasonable, the margins will increase and the

effective use area of paper will decrease. Books with more short lines, such as

a collection of poems in horizontal rows, use a 32-format book, with a lot of

blanks in the cut and order, and use more paper. If you use a long and narrow

36 format, you can save paper. If the format is too small, the number of folds

and the loss of smooth edge materials will also be greater. In order to

facilitate printing, try to avoid or use less irregular format, which can

reduce printing costs.

2. Paper

materials

Paper

materials account for a large proportion of book costs, accounting for more

than 40%. Therefore, the rational selection of paper materials is an important

aspect of reducing the cost of books.

Ordinary

books, such as compendiums, learning materials, literary and artistic readings,

etc., paperbacks can use 52g/m2 (hereinafter referred to as 52g) letterpress

paper, and hardcovers can choose 60g or 70g offset paper.

Songs

and children's books can use 60g paper in monochrome, and 80g offset paper in

color.

Textbooks

generally use 49-60g letterpress paper; for reference books, paperback books

use 52g letterpress paper, hardcover books can choose 40g dictionary paper, and

general technical standards can use 80�?20g

offset paper.

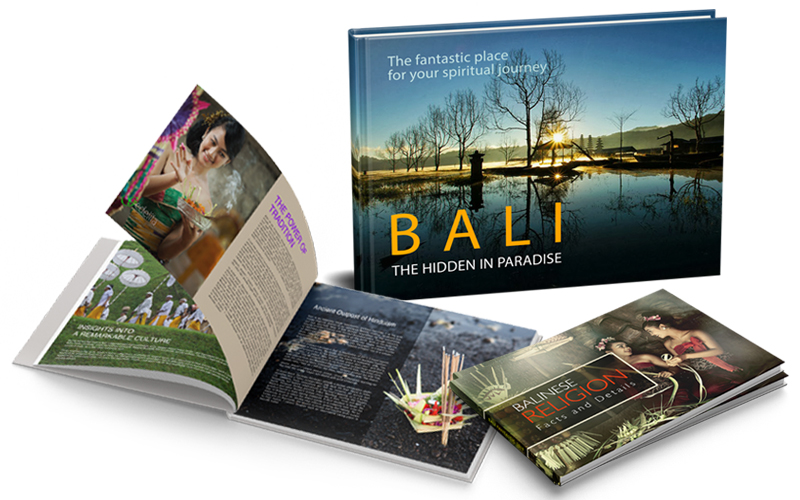

To

Pictures

and picture albums, generally 80�?20g

offset paper or 100�?28g

coated paper; can choose offset paper or coated paper and weight according to

the degree of fine printing of the album, format. New Year pictures and posters

generally use 50-80g single-sided offset paper, comics use 52-50g relief paper,

and high-end exquisite small pictures use 256g glass cards.

Magazine

generally uses 52-80g paper, monochrome generally uses 60g writing paper or

offset paper, and color generally uses 80g double-print paper.

Covers,

inserts and interleaf pages of books and magazines: generally use 100-150g

paper for covers up to 200 pages, 120-180g paper for more than 200 pages;

80-150g paper for interleafes; interleaf pages are generally between 80-150g

depending on the thickness of the book Optional.

For

the same type of paper, the heavier the gram, the higher the price. The weight

of the text paper increases, and the thickness of the spine also thickens.

Sometimes it is necessary to adjust the gram weight and opening number of the

cover paper, which will produce a series of ties. Often increases the cost of

paper.

Carefully

select paper materials, but do not cut corners. For example, printing a finer

screen version with ordinary paper will blur the layout, all ineffective, and

cause waste. Another example is that newsprint can be used for ordinary

reading, while newsprint that is easy to weather cannot be used for books that

need to be stored for a long time.

3. The number

of pages of the book

When

composing plates, try to avoid zero pages. Because in addition to the main

text, a book has other parts such as four envelopes, title page, preface, table

of contents, copyright pages, etc., and each part may use different paper, so

the total number of pages of the same paper type is made up to 4. Multiples of

is not difficult.

4.

Binding form and layout design

Commonly

used book binding forms include saddle stitching, flat stitching, stitch

binding, perfect binding, etc. Saddle stitching, stitch stitching and perfect

binding can be designed to make the center spread smaller. If it is a

flat-stitched form, the center of the center spread should be relatively large,

because the stitching of a flat-stitched book takes about 5mm.

Contact

us for more information about the cost of Chinese printing. We will guide

you how to reduce your printing cost.

Email:[email protected]

Email:[email protected] Tel/WhatsApp:+86 13580851182

Tel/WhatsApp:+86 13580851182